Featured

What Is Drop Forging

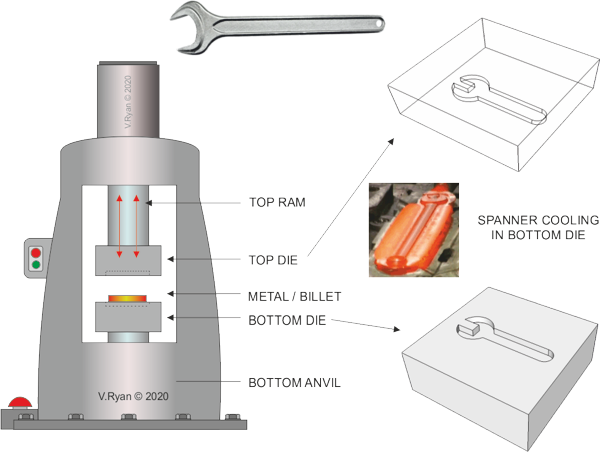

Adequate draft is provided. A workpiece is inserted into a die and then hammered until it has assumed the shape of the die.

Times could be obstacles from the fall.

What is drop forging. Drop hammer forging process is a popular procedure from the forging business for the production of gear aerospace components turbine blades as well as other high-performance steel components. Drop forging basically metal shaping process in which Metal is heated below melting point andthrough hammering process its moulded in desired shape. Drop forging - Hammering hot metal into dies.

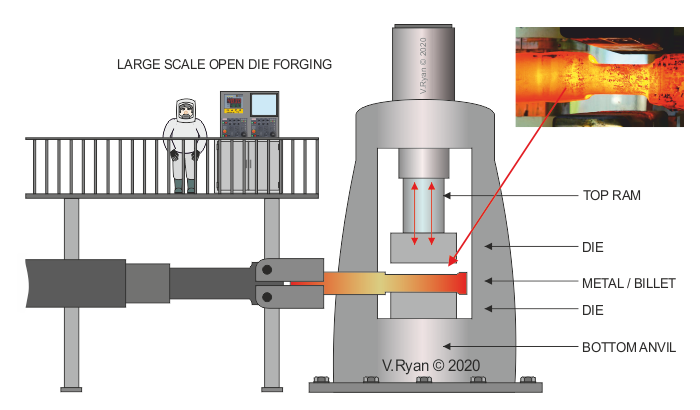

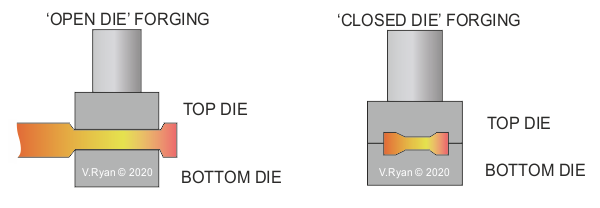

The lower die is a stationary part while the upper part is a moving hammer dropped onto the workpiece in order to deform it. Drop forging is a metal shaping process the metal to be formed is first heated then shaped by forcing it into the contours of a die this force can be in excess of 2000 tons. If the upper die or hammer is dropped the process is known as drop forging.

Drop forging Hammering hot metal into dies. Usually at least 3 for. Closed Die Drop Forging The dies part along a single flat plane whenever possible.

Drop forging is a process that uses a pair of impression dies and a heavy hammer to form and compress metal bars or billets into complex shapes. In most forging an upper die is forced against a heated workpiece positioned on a stationary lower die. Press forging - instead of forcing hot metal into a die with a hammer blow it is pressed into the die with hydraulic.

Four of the most common include. In addition to cold hot and flat forging presses drop forging. It is used when a large quantity of certain components with sound and good quality forgings are to be produced.

If not the parting plane follows the contour of the part. Drop forging is a metalworking process that gradually shapes a heated piece of metal called an ingot. It involves forming the ingot with repeated blows from a hammer or die that is raised and then dropped onto the part flattening it or forcing it into a mold.

In principle drop forging is the most widely used forging method. Drop forging is the most widely used forging process. Drop forging is a metal forming process.

The parting surface is a plane through the center of the forging and not near an upper or lower edge. What Is Drop Forging. The drop forging process can be performed with the material at various temperatures.

The impression or die cavity is the desired shape of the final forging. Automotive truck bus defense aerospace and energy which makes it imperative for buyers sourcing drop forged components to understand the process types value stream map technical advantages and early supply partner involvement to. It is used for example to manufacture planes ships or car parts as well as in the design of various industrial products.

Drop forging is now a major global industry supplying high strength components for many of the worlds most innovative products and industries. The benefits of hot forging include the metal being more flexible and easier to work with than cold forging allowing more customized parts to be manufactured due to this malleability. Drop forging refers to a method of closed die drop forging where a heated steel billet is placed on a lower die mold block.

While overhead the die-equipped ram hammer drives down or drops down forcing the metal to fill the contours of the two die blocks. In drop forging-steam compressed air electricity steam or rollers. For this process forming tools are moved towards each other and push the material in a specific direction.

Drop forging is a hot forging process which DIN 8583 classifies as a pressure forming process. Drop forging is a type of closed-die forging. Drop forging Process of shaping metal and increasing its strength.

Press forging instead of forcing hot metal into a die with a hammer blow it is pressed into the die with hydraulic pressure. The bigger the forging the bigger the hammer would be used. To increase the force of the blow power is.

Drop Forging Process. What is drop forging used for. Roll forging - The hot metal is pressed between two rollers.

What is drop forging.

Drop Forging The Closed Die Impression Die Drop Forging Experts C 2021 W H Tildesley Ltd

Drop Forging The Closed Die Impression Die Drop Forging Experts C 2021 W H Tildesley Ltd

Drop Forging Uk Forge Manufacturing Drop Forged Components C 2021 Brooks Forgings Ltd

Drop Forging Uk Forge Manufacturing Drop Forged Components C 2021 Brooks Forgings Ltd

Why Drop Forgings Retractable Awning Dealers Nuimage Awnings

Drop Forging Open Die And Closed Die

Drop Forging And Press Forging Difference Youtube

Drop Forging And Press Forging Difference Youtube

What Is Drop Forging Closed Die Impression Die Knowledge Jingjiang Jinlun Machine Manufacturing Co Ltd

Drop Forging Hammer Forging Hammer Tools Drop

Drop Forging Hammer Forging Hammer Tools Drop

Drop Forging Hot Metal Shaping Hammer Download Scientific Diagram

Drop Forging Hot Metal Shaping Hammer Download Scientific Diagram

Drop Forging Closed Die Forging

Drop Forging Closed Die Forging

Drop Forging Vs Press Forging Milwaukee Forge

Drop Forging Vs Press Forging Milwaukee Forge

Comments

Post a Comment